About Us

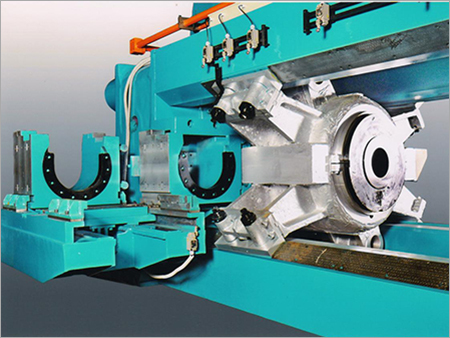

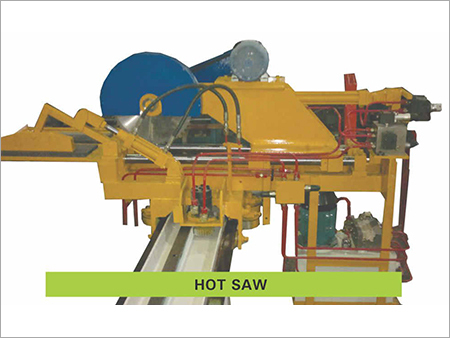

SPM Controls is a Karnataka, India based organization which commenced its business journey in the year 1994. Capitalizing on our almost 21 years of experience and adequate knowledge, we have been able to carve a niche as a prominent Manufacturer, Exporter and Supplier of Hydraulic Press, Hobbing Press, Hot Log Shear, Hot Saw, Hydraulic Cylinder Power Packs, Moulding Press, Pipe Forming Press, Puller and many other equipment.

Our Hydraulic Presses and available in different capacities ranges from 6 to 2000 tons in various types such as C Frame, Closed Frame, Four Pillar and Four Column Prestretched Tie Rod. The clients can purchase the Hydraulic Presses from us with several optional features like ejectors, blank holder, mechanical knock-outs, shock absorbers, quick die change systems, transfer systems etc. Apart, we are amongst the few companies who have the capacity to produce 2500 M.T nonferrous metal extrusion presses. The companies whom business requirements we are successfully meeting are TATA Group, LTVS Group& RANE Group.

Product Portfolio

Our firm is engaged in manufacturing, exporting and supplying the following machinery and similar equipment to the clients at affordable rates:

|

|

Assurance of High Quality

The quality which we maintain in our products enable us to achieve a trustworthy position in the domestic market. Our entire gamut of machines and equipment are known for their top quality as high grade components are fitted in them. The superior quality spare parts integrated in our products not only enhance their functional life but also the overall functionality. Through stringent quality examinations, the entire gamut is passed through and tested with the aid of sound analyzing instruments and tools. On the grounds of corrosion resistant nature, rust proof finishing, dimensional accuracy, durability and fluency in performance, the end products are inspected by experts.

Sound Infrastructure Set Up

For running the company smoothly, we have developed a sound infrastructure at Belgaum, Karnataka. To install latest technology and modern machines, large part of our capital is being invested by us. These amenities are time to time upgraded by our technicians in accordance to the latest developments of the respective work sphere. By upgrading our equipment and tools, we are able to enhance production capacity and quality of the finished products. In accordance to the expertise of our employees, we have divided the whole infrastructure into procurement, production, quality testing, packaging, accounts, sales & marketing etc. departments.